Algal Biomass to Produce Carbon Negative Plastics

I'm going to attempt to outline a fairly complex and counter intuitive problem and misconception many people have.

First let me ask you a question. If I plant a tree, am I reversing global warming?

Think about it.

You might say, well yes, trees suck up carbon dioxide and turn it into more tree. Yes that is true. But what happens when the tree dies? It decomposes and returns that stored carbon into the atmosphere again as carbon dioxide. Any natural living process is inherently carbon neutral not carbon negative. Okay so what then is a carbon negative process?

There is one major process on earth, and that is the synthesis of coal and oil. These hydrocarbons get formed because over large timescales (geological) and pressures (the weight of oceans), biological matter (like algae) get compacted and liquefied into hydrocarbons. These hydrocarbons get trapped in rocks and are effectively removed from the carbon cycle. Trapped matter will have no interaction with the rest of the carbon cycle.

Carbon dioxide, carbonates, carbonic acid, and organic carbon all intermingle in this reversible cycle. Humans have perturbed this equilibrium since the industrial revolution by the burning of fossil fuels and the subsequent release of carbon dioxide into the atmosphere. The carbon cycle is responsible for the exchange of atmospheric carbon dioxide for solid or liquid carbon-containing molecules. The imbalance in the natural equilibrium of the carbon cycle is because of the following: The burning of previously sequestered carbon (for example coal, oil) into carbon dioxide occurs on human timescales whereas the sequestration of gaseous carbon dioxide into carbonaceous rocks occurs on geological timescales.

This imbalance can only be corrected by introducing a process that sequesters gaseous carbon dioxide on a human timescale (< 100 years). Unfortunately the natural sequestration processes that occur on Earth are energetically “free” from a human frame of reference and accelerating the rate of carbon sequestration is energetically expensive. Energy intensive processes tend to have a high carbon footprint, so careful life cycle assessment (LCA) techniques need to be used to determine if a Carbon Capture and Storage (CSS) technique is actually effective.

Life cycle assessment is a method of book keeping for tabulating the carbon and energy footprint of a good from its inception to its destruction. This form of record keeping and tabulating is what I will be using for the rest of this post. I would implore you to read my full report posted at the bottom of the blog post if this whole topic interests you. I will continue this post with a very high level summary.

Okay lets figure out how to trap carbon and remove it from the cycle

A review of common methods are found in my full report below. Carbon can be captured and stored using gas systems (exploiting solubility and thermodynamics with aqueous ethanolamine), or pumping liquified carbon dioxide into sub-surface reservoirs.

Honestly, most methods have terrible deal-breaking drawbacks. Gigantic energy consumption for one (and guess what, the production of energy causes more carbon dioxide to be formed!) or unknown environmental damage.

Whats a hard to break down, carbon containing material?

In this report we will attempt to outline routes to create artificial carbon negative materials such as polymers. In the absence of intense ultra-violet radiation, plastics such as high density polyethylene can have an exceptionally long service life. Under laboratory conditions, only ~0.1 % of the carbon in polyethylene is degraded per year back into carbon dioxide by UV-light and microbes (Pritchard, 1998). For the present study, we will be producing 1 kg of cross-linked high density polyethylene which according to the degradation rate from Pritchard will fully degrade to 1 g in nearly ~7000 years. Polyethylene has the lowest oxidation rate when compared with polypropylene, polyamide 6 and polybutylene terephthalate (Gijsman, Meijers, & Vitarelli, 1999). An example of long term carbon storage would be burying plastics to avoid UV exposure. More economically viable, but shorter term carbon storage, would be to sell these carbon negative products, but expecting that they will photo-degrade eventually (< 7000 years).

If we can't wait for geological timescales to reverse our damage and create new oil, we will have to create our own. Instead of burying oil and coal, we can bury plastic.

I came up with a few ways to create plastic from natural sources, and i tabulated how much energy and carbon dioxide it took to make them. The goal was if I could find one method that absorbed more carbon dioxide then I spend creating the plastic, then the idea has some merit.

Fermented Ethanol Route

Okay what if we grow algae in reactors, dry them out, ferment them with yeast (making a crude algae moonshine), distill off the ethanol, catalyze the ethanol into ethylene, then polymerize the ethylene? Yes, that is indeed quite a mouthful.

Turns out this is way too many steps! Growing algae takes energy, drying it takes a tremendous amount as well. As does every other step. Okay what else can we try? Any simpler processes?

Algae Gasification Route

Lets try a different method. What is gasification you might say? If you heat biomass at high pressures and temperatures in an oxygen deficient environment, you can create something called synthetic gas (commonly called syngas). Its an equilibrium mixture of carbon dioxide, water, carbon monoxide and hydrogen. By injected water in the presence of syn gas (at high T and P still) we can shift the equilibrium to produce more CO and hydrogen. When the stoichiometry gets just right, and in the presence of catalysts such as the amazing porous zeolite HZSM-5, the syngas will transform into methanol.

Pure methanol can be catalyzed into ethylene at certain temperatures and pressures once again in the presence of catalysts, which again can be polymerized into polyethylene.

Assuming production is done in a dirty American state (dirty, energywise :) ) such as Texas or Florida where 1 MJ of energy creates 194 g of carbon dioxide, below is the life cycle inventory for each step in the process. By convention, negative values are inputs and positive values are outputs.

Metabolic By-Product Ethanol Route

Algenol Biofuels is a biotechnology and biofuel firm founded in 2006 located in Bonita Springs, Florida. Algenol Biofuels not only is involved in the production of fuel from algae, but has a department devoted to the genetic manipulation of various candidates of potential fuel-producing algae and bacteria. Patented genetically modified blue-green algae (cyanobacteria) over-express the genes responsible for the production of two enzymes: pyruvate decarboxylase and alcohol dehydrogenase. These two enzymes are involved in the metabolic pathway that allows cyanobacteria to produce ethanol as a metabolic by-product. The resulting ethanol gets excreted through the cell wall. The full metabolic pathway is shown in Figure 3a.

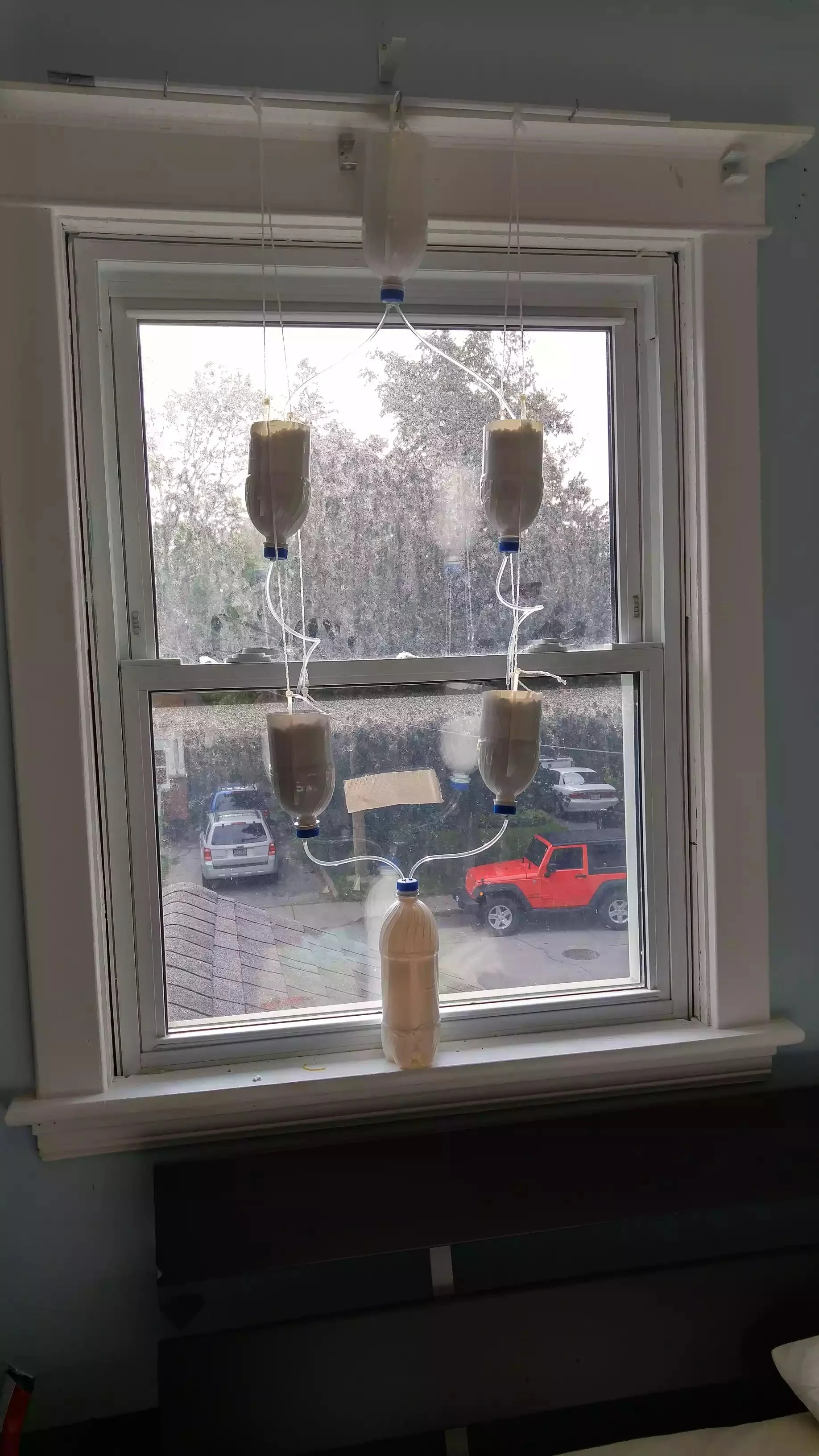

Once excreted through the cell wall, the culture medium housed in each 1.5 x 15 m photobioreactor (polyethylene walls) evaporates during the day. A greenhouse effect causes the inside of the photobioreactor to heat up and ethanol/water mixtures to condense on the surface of the chamber. The water/ethanol mixture trickles down the sides of the reactor and collects in collection troughs as shown schematically in Figure 3b. The amount of ethanol excreted from the cells creates an incredibly dilute ethanol in water mixture. However, the binary ethanol-water system exhibits a very strong non-ideality from Raoultian behavior, causing a large increase in the mole fraction of ethanol in the vapor phase despite having a small amount in the liquid phase (Dalager, 1969).

A major advantage of this type of system is that it is a “no-harvest” approach. There is no need to open the tanks and open the culture to potentially devastating competing microbes. This technique also avoids the energy intensive harvesting/dewatering steps outlined in the Algae Growth to Algal Biomass unit process in the Biomass Gasification section of this report. There are two significant down-sides of the no-harvest approach however. Firstly, the growth rate of the algae is low due to the cell’s high energy expenditure in producing ethanol – therefore biomass yield is low. However biomass is merely a co-product in this process. The biomass extracted is not sufficient to be used as energy to fuel the operation since the cultures are only replaced 1 – 2 times a year. In addition to this, there is a high energy cost in distilling the ethanol from dilute concentrations to fuel-grade quality.

Figure 3. a) Metabolic pathway for the conversion of CO2 into ethanol (Algenol Biofuels, 2006). b) ethanol/water collection system (Algenol Biofuels, 2006). c) vapor-liquid equilibrium data of the binary ethanol-water system (Dalager, 1969).

The above system was the most efficient. Its LCA results are summarized in the below table.

Conclusion

A comparison has been made between two potential routes to produce high density polyethylene (HDPE) using autotropic algae and cyanobacteria as a source of carbon. Algae have the potential to be grown in outdoor ponds, dewatered, gasified into synthesis gas, converted to methanol, converted to ethylene then subsequently converted into polyethylene. This process uses 148.85 MJ/kg HDPE and has a net carbon dioxide emission of 6.84 kg CO2e/kg HDPE (taking into account the carbon dioxide required for algal growth). The second route to produce algal plastics is much more promising and involves genetically modified cyanobacteria. These cells can excrete ethanol directly into their culture media, then after rigorous purification and distillation, the fuel grade ethanol can be converted into ethylene. The ethylene can then be polymerized into HDPE. This process uses 17.74 MJ/kg HDPE and has a net carbon dioxide emission of -1.25 kg CO2e/kg HDPE (taking into account the carbon dioxide required for algal growth).

While the metabolic ethanol by-product route does seem promising from an energy intensity point of view when compared to both gasification and fossil-fuel derived HDPE, cost is still an issue. Economic viability was not analyzed in this study, and it is a fair assumption that fossil-fuel plastics will be cheaper today in 2016 due to the economies of scale present in the petroleum industry, and the low price of crude oil (< $40/barrel USD).

As a materials engineer, producing genuinely sustainable materials that have the potential to lower the amount of greenhouse gases in the atmosphere is an exciting prospect. It is the duty of the engineer to design for the benefit of society, and to design with the triple bottom line in mind. Carbon negative algal plastics have the potential to replace fossil fuel derived plastics, and sequester carbon at the same time. As new engineers it is our duty to adapt to the challenges of the 21st century where climate change is seen as a real societal threat. The traditional engineering profession is en route for sweeping changes as our value to society will shift from technical number crunching to critical thinking & problem solving. We must use our engineering knowledge, in the case of this paper, knowledge of materials engineering, chemical engineering, chemistry, and holistic life cycle analyses to propose alternatives to reduce our society’s dependence on non-renewable fossil fuels.